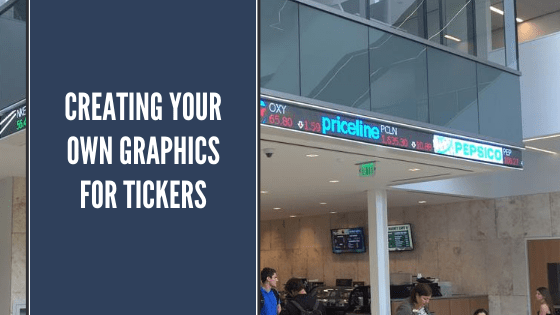

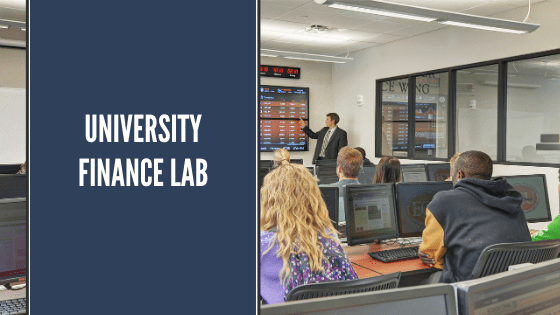

Indoor Ticker Hardware (Commercial)

All Rise tickers are full color, and meet rigorous quality standards. With our tickers, you can build what you want to fit the space you need. For instance, you can go straight, wrap it around corners, run it up a wall vertically, curve it, daisy chain them together, etc. You can make it unique to your space!

Indoor Ticker Hardware (Consumer)

If you are looking for something simple, standard and available to ship within 48 hours we stock a number of popular sizes in our Las Vegas warehouse. Our consumer lines are full color and and compatible with the Rise Ticker Mobile App.

Outdoor Ticker Hardware

At Rise, in addition to indoor displays we also offer outdoor units designed to withstand the elements and compete with sunlight. We offer multiple heights to provide the ideal character height for longer viewing distances.

Digital Signage

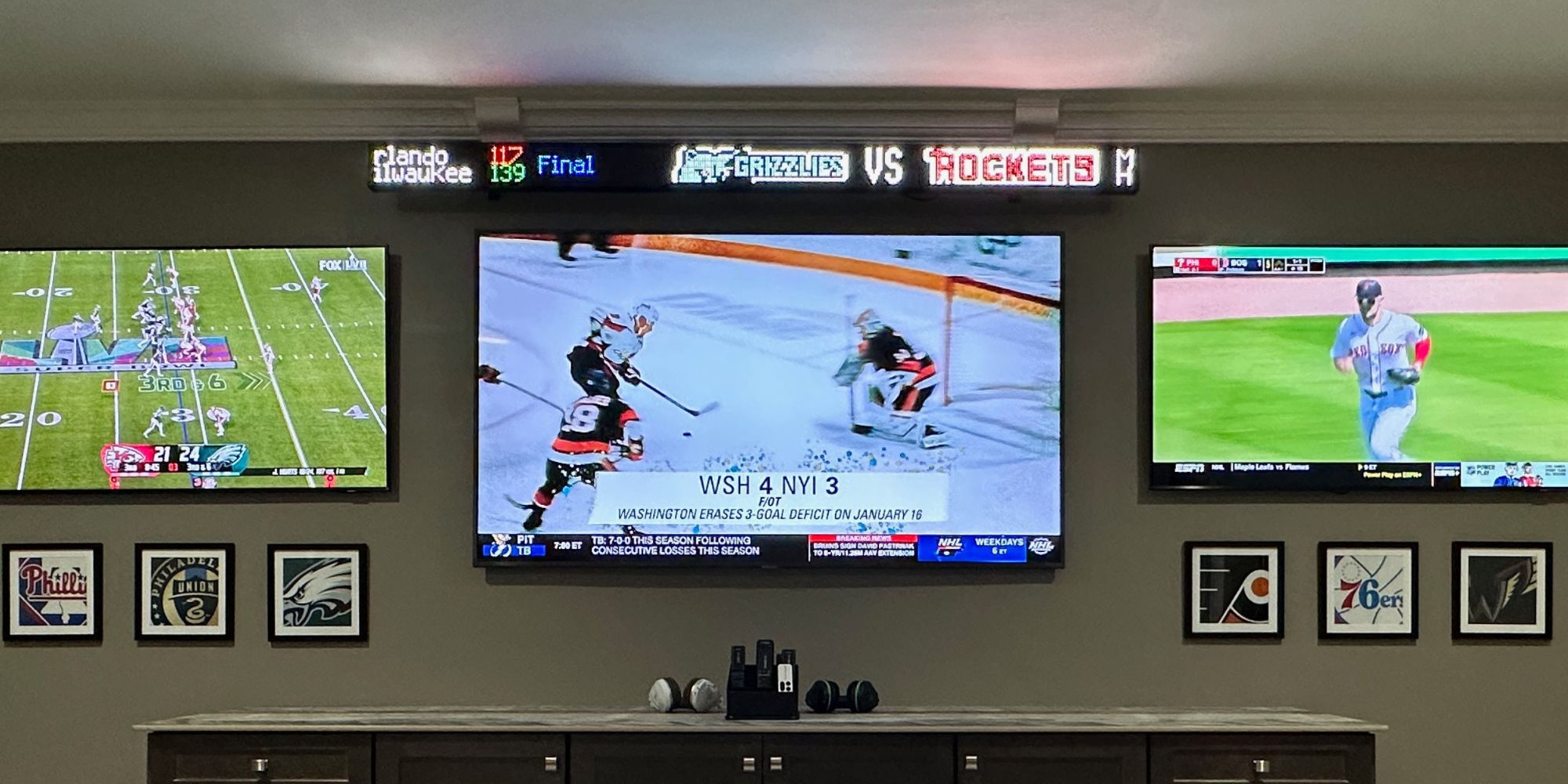

In addition to ticker displays our mobile app is designed to schedule content on any flat screen TV. Just plug a Rise Media Player into the HDMI port and display live market updates.

LED World Clock

If you are looking for an easy way to create a global atmosphere and keep track of different times zones around the world check out our 6 zone world time clocks.

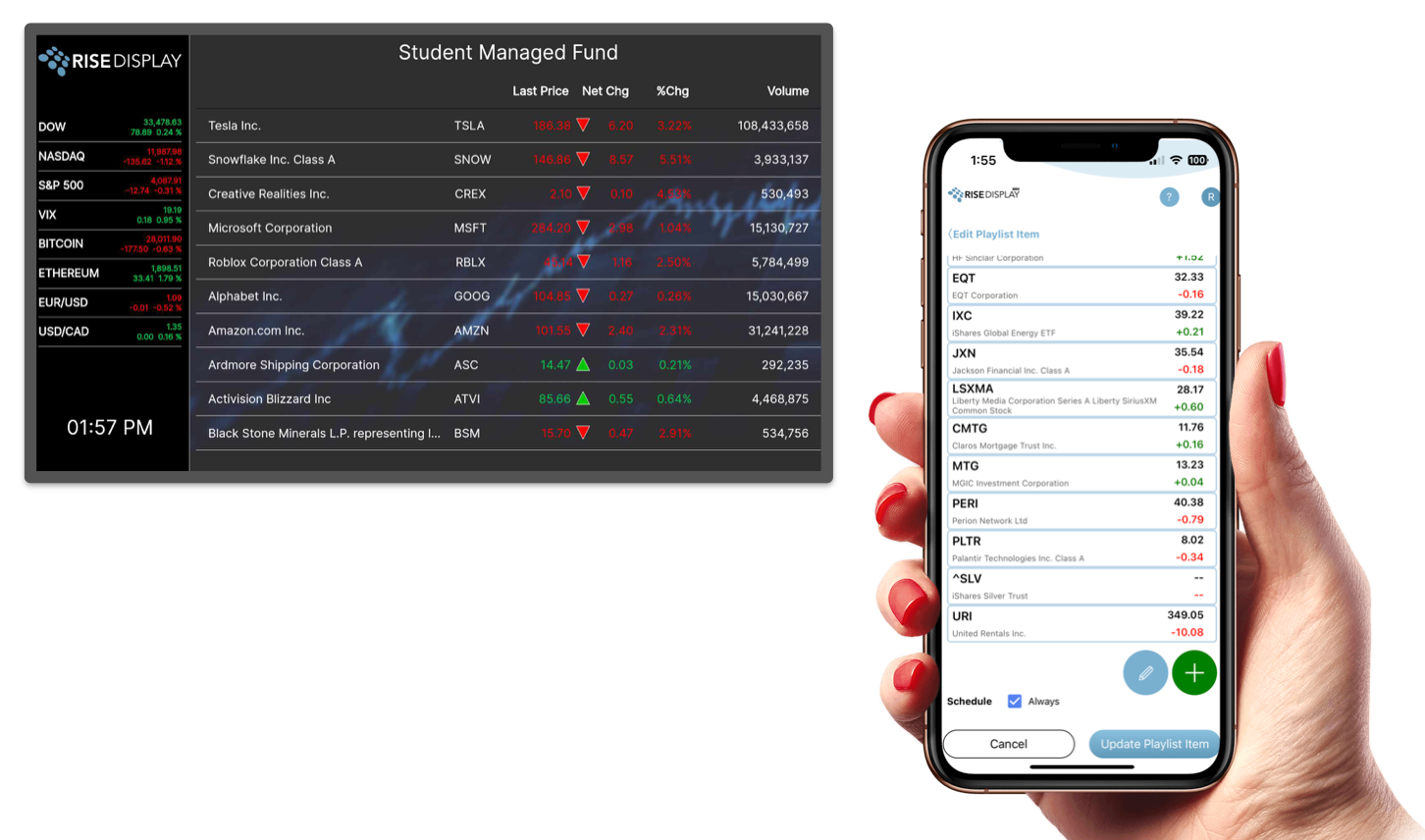

Rise Ticker Mobile App

With our many content options, you’ll be able to display your messages alongside licensed real-time data feeds, with logos. Whether you’re looking to display stock quotes, sports scores or the latest headline news, Rise Display is the company to trust. The content is completely integrated with our ticker hardware and designed to run for years with no complications.